Polishing Compounds

Diamond Polishing Paste (DIA)

Oil-based or water-based polishing pastes, high-quality polishing grains homogenized in ointment, high quality material, accurate and resistant to wear over time.

Used for polishing soft to hard metals, gems, ceramics, glass, sapphire, lenses, composite materials, precision seals and more …

Silicon Carbide Polishing Paste (SC)

Oil or water based polishing pastes, hard polishing material within ointment, high grinding rate and medium resistance to wear.

Used for polishing steels, metals, polymer rpoducts, ceramic materials, glass, epoxy paint and more …

Aluminum oxide pastes (AO)

Oil or water base compounds, powder with round to sharp edges, moderate strength and rate, medium resistance to wear.

Uses: polishing metals, polymer products, ceramic materials, glass, epoxy and more …

|

GRADE SIZE |

|||||||||||

|

80 |

120 |

180 |

220 |

320 |

400 |

600 |

1,250 |

2,000 |

3,800 |

12,000 |

Mesh USA |

|

177 |

125 |

80 |

60 |

45 |

37 |

20 |

10 |

6 |

3 |

1 |

Micron |

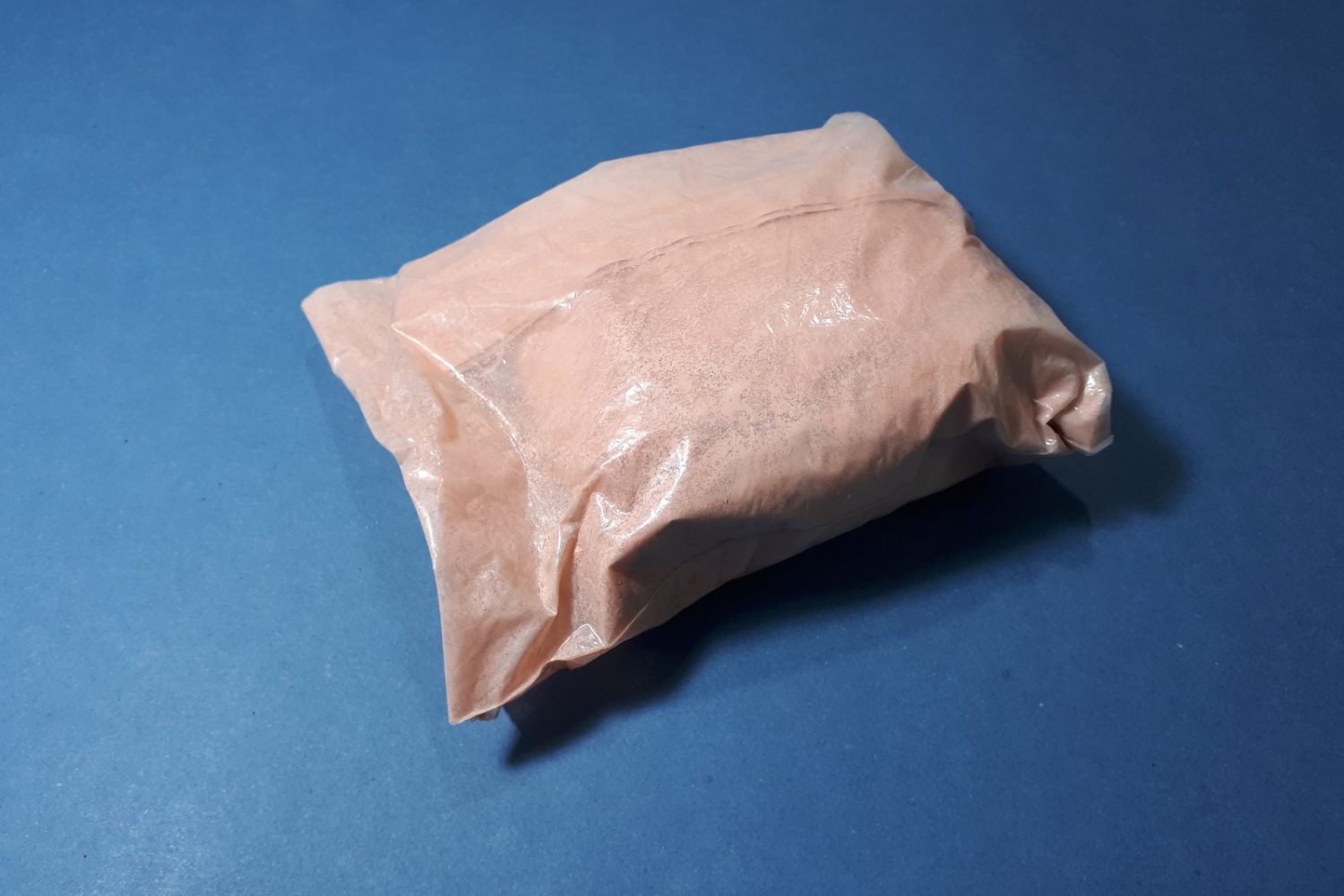

Cerium Oxide Pastes (CO)

Pack with dry powder without lubricant, mix the powder with filtered water at a ratio of 10% water to powder (1:10) and add water until the required viscosity is obtained. Comes in colors: light brown, white and red.

Uses: Final polishing of glass (transition from transparent to transparent)

| GRADE SIZE | |||

| 10,000 | 20,000 | 26,000 | Mesh USA |

| 1.5 | 0.5 | 0.3 | Micron |

Hard polishing pastes for polishing wheels

.Pack with dry powder without lubricant, mix the powder with filtered water at a ratio of 10% water to powder (1:10) and add water until the required viscosity is obtained. Comes in colors: light brown, white and red.

Cerium Oxide Pastes (CO)

Blue paste

Rough polishing, recommended for hard metals, use with yellow cloth wheel after polishing film, Process: Grinding → Polishing → and Blue Paste & yellow wheel.

Brown paste

Rough to semi rough, recommended for all metals, use after blue paste before the final stage. Use with yellow or white polishing wheel, yellow for harder metals and initial polishing steps.

Process: Grinding → Polishing → and Blue Paste with yellow wheel → Brown Paste & Yellow/White wheel.

White paste

Final polishing step, recommended for all metals, use with white fabric wheel.

Process: Grinding → Polishing → and Blue Paste with yellow wheel → Brown Paste & Yellow/White wheel → White Paste & White wheel.

Green paste

Green paste fine finish with mirror surface, recommended for soft metals.

Process: Grinding → Polishing → and Blue Paste with yellow wheel → Brown Paste & Yellow/White wheel → Green Paste & White wheel.