סיבים אופטיים

סיבים אופטים הם מובילי אור שקופים וגמישים עד רמה מסויימת, מיוצרים בדרך כלל מזכוכית צורן, סיליקה, או פולימר שקוף, הסיבים מיוצרים בקטרים שונים כתלות בצורך ובדרך כלל כוללים ליבה.Core זהו למעשה גליל זכוכית המוקף בחיפוי קונצנטרי שקוף העשוי מאותו חומר עם אילוח טיפה שונה Cladding היוצר הבדלי אינדקס אופטי בין הגרעין למעטפת ומונע מהאור הנע בתוך הליבה לצאת. לסיבים אופטים שימוש נרחב בתקשורת, LIDAR, יישומים רפואיים, רכבים, תעופה, עיבוד חומרים, רפואת שיניים, אסטטיקה, אופטיקה, לייזר ועוד. סיבים אופטים המשמשים לתקשורת נפרשים למרחקים קצרים וארוכים של עד מאות ק"מ, סיבים אלה בעלי יכולת העברת נתונים גבוה מאוד (רוחב פס) והפסדי מידע מינימליים. כמו כן אנו מספקים סיבים לג'ירוסקופ, סיבים ללייזר ומגברים אופטיים, סיבים וכבלים לבקרה, כבלים לתשתיות אופטיות וסיבים לגלאים על כולם יפורט בהמשך.

ניתן לקבל הצעת מחיר לתכנון אופטי וייצור של סיבים שאינם סטנדרטיים או כאלה שמעולם לא יוצרו, סיבים עבור אפליקציות קיימות וחדשות, במיקרים אלה איפיון דרישה יכלול יכולות ייצור ודרישות מוצר.

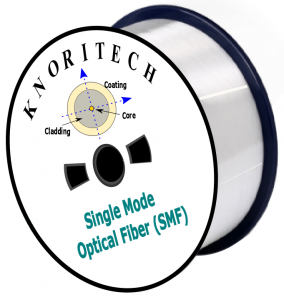

Single Mode Fibers

Single-Mode Optical Fiber (SMF) designed to carry only a single mode light, obtained by combining Maxwell's equation and boundary conditions. Waves can have the same mode but have different frequencies. This is the case in single-mode fibers, where we can have waves with different frequencies, but of the same mode distributed in the fiber core in the same way Single mode fibers can permit transmission over long distances with high data transfer rates (bandwidths) and minimal losses.

Photonic Single-Mode Fiber Series for Component (PH-SMF) – Are specially developed for optical components with stricly requirement for bending resistance properties. The fibers are manufactured by PCVD process with Ge/F co-doped material system and special waveguide structure. The fibers have tight geometric and optical specifications. They are compatible with G.652 fiber and has excellent macro-bending performance which makes it very appropriate for the mini components. The fibers meet the standards of ITU-T G.657.A1/G.657.A2/G.657.B3 and suits full range applications from 1260nm to 1625nm. The Ge/F co-doped material system design provides excellent macro-bending attenuation and good fused-taper performance. The macro-bending performance of PH1011-C and PH1012-A has been significantly improved with special "trench" waveguide structure and meets the requirements of G.657.A2 and G.657.B3 standards. PH1012-A is specially developed for very small bending radius and compact components and modules in C band with excellent bending resistance.

Matched-Cladding Single-Mode Fiber for Component (CSF) – Particularly developed for optical components. The fiber offers excellent geometric and optic specifications by PCVD process. The fiber adopts special matched-cladding structure and Ge/F co-doped material system to achieve material matching, which makes the fiber can be used for taper couplers. CS1012-A and CS1013-A are suitable for light source coupled single mode output in 580- 850 nm visible band. CS1015-A and other 980/1060 nm fibers have excellent tapering performance. CS1011-A and CS1011-B are specially developed for tapered components in 1310 nm. CS1018-A and CS1018-B are specialty developed for tapered components in 1550 nm. And the macro-bending performance of S1018-A is better than G.657A2

Dispersion Compensating Fiber (DCF) – DCF has broad band dispersion compensating of DWDM network and extremely low residual dispersion, 80% – 120% slope compensation in C/L band, low insertion loss and high negative dispersion coefficient, high figure of merit (FOM), low PMD, customized encapsulation type, dimension, connector type and jumper length and excellent splicing characteristics, spliced by one time discharge. Main applications are: Single mode fiber backbone and metropolitan area networks based on recommendation G.652, DWDM networks, SDH network, CATV and Dispersion adjustment

Photonic Single-mode Fiber Series for Component (PH-SMF) – Is specially developed for optical components with strict requirement for bending resistance properties. The fibers are manufactured by PCVD process with Ge/F co-doped material system and special waveguide structure. The fibers have tight geometric and optical specifications. They are compatible with G.652 fiber and has excellent macro-bending performance which makes it very appropriate for the mini components. The fibers meet the standards of ITU-T G.657.A1/G.657.A2/G.657.B3 and suits full range applications from 1260nm to 625nm.

The Ge/F co-doped material system, design provides excellent macro-bending attenuation and good fused-taper performance. The macro-bending performance of PH1011-C and PH1012-A has been significantly improved with special "trench" waveguide structure and meets the requirements of G.657.A2 and G.657.B3 standards. PH1012-A is specially developed for very small bending radius and compact components and modules in C band with excellent bending resistance. Fiber characteristics shows: Tighter geometric and optic specifications, Excellent splicing performance, Excellent compatibility with the G.652 fiber, Excellent macrobending resistance, Excellent micro-bending resistance and High reliability enhanced by 200kpsi. Main applications are: Bending sensitive condition/mini component, Pigtails/Patch cords, Connectors, Couplers, Miniaturized integrated erbium-doped fiber amplifier (EDFA), DWDM Components

Multimode/FewMode/MultiCore/EDF/FOM/SIMMF/DTS - Fiber Optics

Few-mode Fiber (FMF)

The MDM transmission system uses the limited orthogonal modes in few mode fiber (FMF) as the independent channels to carry out information transmission to multiply the transmission capacity of the system. The FMF uses different modes in the fiber as a new degree of freedom, the spectrum efficiency of the system can be improved successfully by FMF.

The large mode field areas and its nonlinear tolerance is always better than that of SMF, not only improves the capacity of optical transmission system, but also avoid the nonlinear effects. The MDM system based on FMF can solve the future single mode fiber bandwidth crisis.

These fibers are manufacture by PCVD process, which is able to manufacture complex index-profile accurately , can get various types of core layer structure, such as Step-Index, Graded-Index etc. According to different design, 2-mode, 4-mode, 6-mode, 9-mode FMFs and even Ultra-low-loss(ULL) FMFs can be realized.

Multi Core Fiber (MCF)

Multi Core fiber (MCF) is a new kind fiber with several separate fiber-cores co-existed in the same cladding. MCF can achieve low inter-crosstalk in long SDM optical transmission by adopting the sever-core structure and F-doped cladding, which has a typical promising future in optical transmission field. Based on the concept of space division multiplexing (SDM), MCF can realize transmitting several light signals through different channels and is expected as a breakthrough technology against capacity crunch of optical transmission system over a single-mode fiber. With the development of SDM (Space Division Multiplexing) and multi-core fiber sensor technology, multi-core fiber would be a vital branch of fiber development. The level of crosstalk and fiber coating of MCF can also be customization to fulfill your use in transmission, sensor, industry, medical equipment fields and so on.

Erbium Doped Fiber (EDF)

The Erbium Doped Fiber(EDF) meets the most stringent amplifier requirements both for C-Band and L-Band. Through 1480nm or 980nm pump technology. Erbium doped fiber can realize 35nm amplification bandwidth and maintain flatness gain to get ideal power conversion efficiency. Specially designed for high performance, low noise requirements amplifier, for example: Optical-Preamplifier, Booster, and In-Line Amplifier in the WDM communication system. Erbium doped fiber has been optimized through co-doping with Erbium and Aluminum technology to ensure the Highest quality performance.

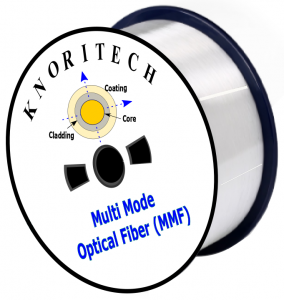

Multimode Fibers

Multi-mode optical fiber (MMF) designed to carry multiple modes of light – the transverse mode, with Modes are the possible solutions of the Helmholtz equation for waves, which is obtained by combining Maxwell's equations and the boundary conditions. Cores diameter size in multi-mode fibers is 50 and 62.5 micron and the Cladding is 125 micron rounded by polymeric coating.

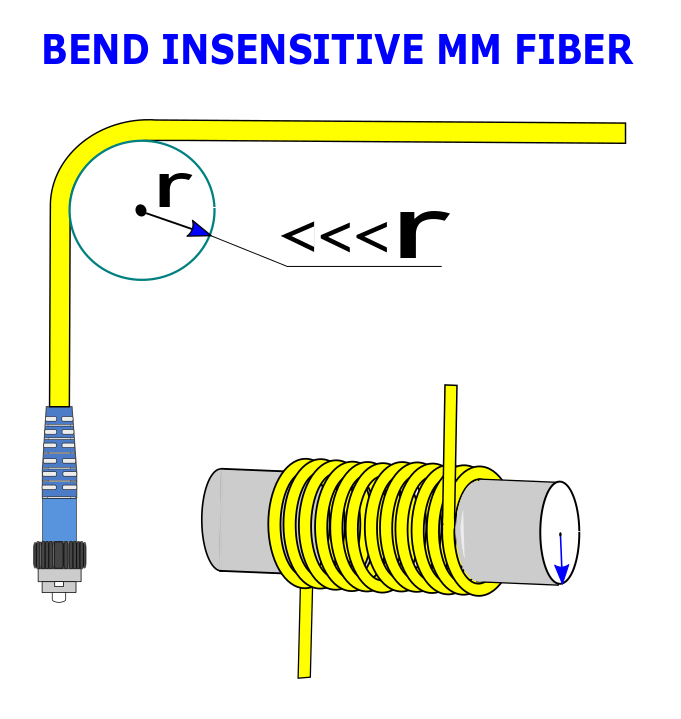

Bend Insensitive Multimode Fibers (FOM)

Bend Insensitive Multi Mode Fibers (FOM) designed to carry only a single mode light, obtained by combining Maxwell's equation and boundary conditions. Waves can have the same mode but have different frequencies. This is the case in single-mode fibers, where we can have waves with different frequencies, but of the same mode distributed in the fiber core in the same way Single mode fibers can permit transmission over long distances with high data transfer rates (bandwidths) and minimal losses.

Step Index Multi-Mode Fiber (SIMMF)

The Silica-cladding multimode fibers with step index profile are comprehensively optimized at both 850nm and 1300nm operating wavelengths. At both wavelengths, extremely low attenuation could be achieved. The SIMM characteristics High coupling efficiency to LED and laser sources, High power transmission, Excellent stripping performance, Applications from visible to near infrared and Customization Information. Series of silica-cladding step index multimode fibers can be customized with different fiber designs, including core diameter, cladding diameter, fiber diameter and NA.

Applications: Fiber sensor and laser transmission, Data communications, local area networks and CATV, Medical apparatus, Optical devices, and connectors

Distributed Temperature System-multimode Fiber (DTS-MMF)

Distributed Temperature System-multimode Fibers (DTS-MMF) adopts advanced plasma chemical vapor deposition (PCVD) process which can insure precise waveguide design and smooth graded index profile. The fiber has an advantages and optimizes preform parameters and excellent optical and geometric properties at long wavelength (1300nm, 1550nm).

Characteristics of Low attenuation at DTS operating wavelength 1450nm, 1550nm and 1650 nm, High bandwidth at C-band (especially at 1550nm), High temperature resistance, Low splicing loss and Excellent bending insensitivity. Additionally, the fiber can resist high temperature by using special coating material. Main applications are: Distributed temperature system. Compared with communication multimode fiber, the advantages of DTS-MMF are as follows:

- Low attenuation at DTS operating wavelength: The lower attenuation of the DTS-MMF at the wavelength of 1450nm, 1550nm and 1650nm can increase the distance of the distributed temperature measurement system

- High bandwidth at 1550nm: According to IEC 60793-1-41-2010 (bandwidth), the actual measured bandwidth at 1550nm of DTS-MMF can exceed more than 1000MHz·km, which effectively improves the spatial resolution of the long-distance distributed temperature measurement system

Polarizations Maintaining Fibers

Polarizations Maintaining Fibers (PMF) Specially designed for fiber optic gyroscopes (FOGs) and polarization-sensitive components applications. This kind of fiber exhibits extremely low attenuation and excellent birefringence characteristics and uses in a variety of demanding applications. This PMF has a precise refractive index profiles, material uniformity and dimensional tolerances with excellent birefringence, low attenuation, and extremely tight tolerances. The PMF has a dual-layer, UV-cured Acrylate coating, high environmental stability performance over the temperature range of -45 ℃ to +85 ℃ (-49 ℉ to +185 ℉ ).

Polarization Maintaining Fiber for Gyroscope

Polarization Maintaining Fiber for Gyroscope (PMF for FOGs) is specially designed for fiber optic gyroscopes (FOGs) and polarization-sensitive components applications. This kind of fiber exhibits extremely low attenuation and excellent birefringence characteristics, precise refractive index profiles, material uniformity and dimensional tolerances, therefore, makes fibers with excellent birefringence, low attenuation and extremely tight tolerances. With dual-layer, UV-cured Acrylate coating, PMF for FOGs has high environmental stability performance over the temperature range of -45 ℃ to +85 ℃ (-49 ℉ to +185 ℉ ).

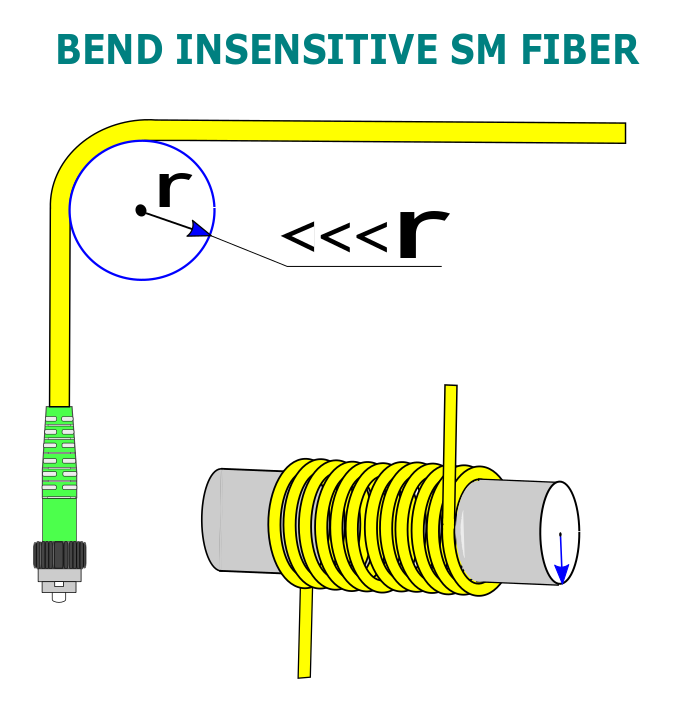

Bending Insensitive Single-mode Fiber (BI-SMF)

Bending Insensitive Single-mode Fiber (BI-SMF) are particularly developed for applications with very small bending radius. The fiber has excellent bending resistance by the special design of waveguide structure, and the minimum bending radius can reach 5mm. By strictly controlling of preform raw materials and drawing process, the fiber has excellent mechanical properties and can meet high proof test level and long spool length requirements.

Characteristics, Low macro-bending loss including L-band, Low micro-bending induced loss, Superior geometry, Excellent mechanical properties, proof test level can reach 200 kpsi And Cladding diameter is 80 μm, realizing the miniaturization of optical fiber In this fiber series, BI1011-A is suitable for optical fiber guidance, and BI1015-A and BI1015-B are suitable for fiber hydrophone. BI1015-B is a small-diameter fiber with a cladding diameter of 80μm, serving the application of compact components. Main applications are: Small-sized optical component, Optical-fiber guidance, Hydrophone and more.

Bend Insensitive Multimode Fibers (FOM)

Bend Insensitive Multi Mode Fibers (FOM) designed to carry only a single mode light, obtained by combining Maxwell's equation and boundary conditions. Waves can have the same mode but have different frequencies. This is the case in single-mode fibers, where we can have waves with different frequencies, but of the same mode distributed in the fiber core in the same way Single mode fibers can permit transmission over long distances with high data transfer rates (bandwidths) and minimal losses.

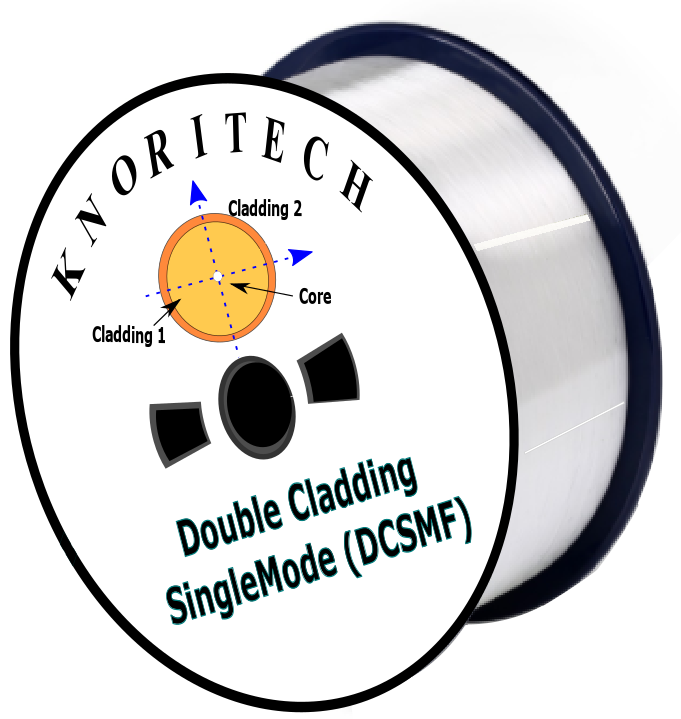

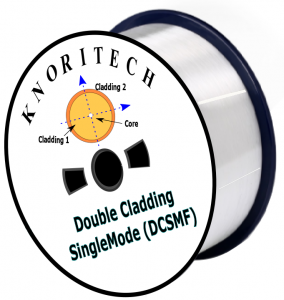

Double/Single-clad Passive Fiber (GDF)

Double/single-clad passive fiber is optimized precisely to match the DC-YDF series, with low splice performance. The fiber has Precise geometry, Low splice loss and Low NA core to maintain excellent beam quality. It is widely used in industrial, medical, military and other fields. Applications: Pulse / CW fiber-laser / amplifier, Materials processing, Pigtails, Fiber combiner, FBG

Double-cladding Ytterbium Doped Fiber (YDF)

Double-cladding ytterbium doped fiber (YDF) is one kind of active fiber applied for 1 micrometer fiber laser. Fiber characteristics shows precise geometry, high ytterbium doped concentration, low NA core, LMA designed, high laser slope efficiency, low photo-darkening and high reliability coating. Laser made by fiber cavity is extensively used in, material processing, medical treatment CW & Pulse fiber laser, industry & Medical applications, high peak-power, high average-power fiber laser, scientific research, and many other fields. Fiber laser is widely used for its advantages of lightness, efficiency, and stability, which are competitively alternative to solid state laser.

Coreless Fiber(CLF)

Coreless fiber, which has no core, includes a solid silica cladding surrounded by a transparent coating material, acrylate. The standard coreless fibers has Φ125μm or Φ250μm silica cladding, besides, customized fibers with special requirements are available.